Four six corner gluing folding machine

SLJ four six corner gluing folding machine

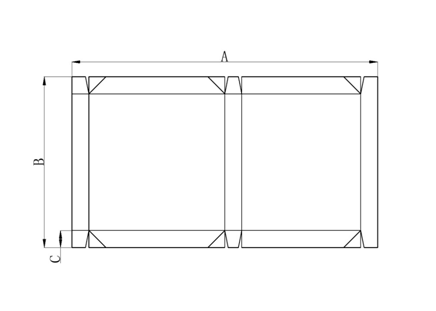

1 Size of 6 folds box and folding box:

Item/model

780Type

980 Type

1050 Type

1450 Type

A

MAX

650

800

900

1200

MIN

300

300

400

400

B

MAX

500

600

600

700

MIN

150

200

200

300

C

MAX

100

100

100

100

MIN

25

25

25

25

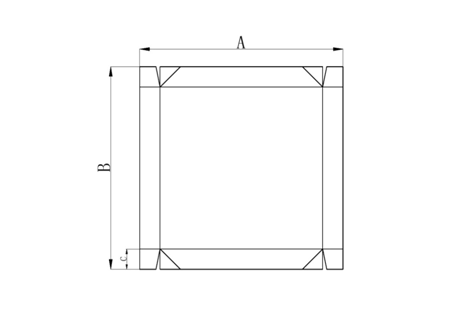

2. Size of 4 corners box and folding box

Item/model

780Type

980 Type

1050 Type

1450 Type

A

MAX

650

800

900

1200

MIN

150

180

200

250

B

MAX

500

600

600

700

MIN

120

150

200

200

C

MAX

100

100

100

100

MIN

25

25

25

25

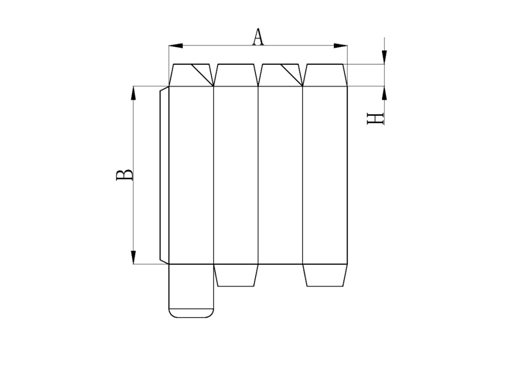

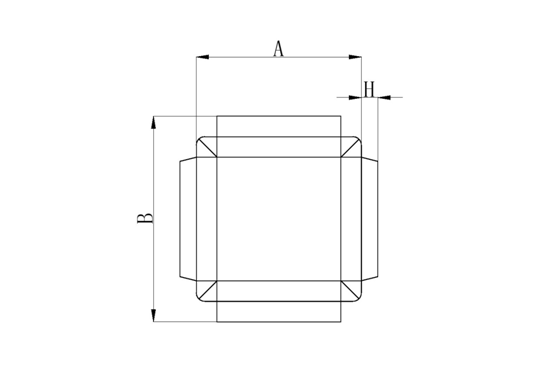

Size of bottom-locked carton and folding carton

|

Item/model |

780Type |

980 Type |

1050 Type |

1450 Type |

|

|

A |

MAX |

750 |

950 |

1020 |

1420 |

|

MIN |

180 |

200 |

250 |

250 |

|

|

B |

MAX |

500 |

600 |

700 |

800 |

|

MIN |

80 |

100 |

120 |

120 |

|

|

H |

MAX |

100 |

100 |

100 |

100 |

|

MIN |

25 |

30 |

30 |

30 |

|

Carton type and size:

|

Item/model |

780Type |

980 Type |

1050 Type |

1450 Type |

|

|

A |

MAX |

750 |

950 |

1020 |

1420 |

|

MIN |

120 |

200 |

250 |

250 |

|

|

B |

MAX |

800 |

900 |

1000 |

1200 |

|

MIN |

60 |

60 |

80 |

100 |

|

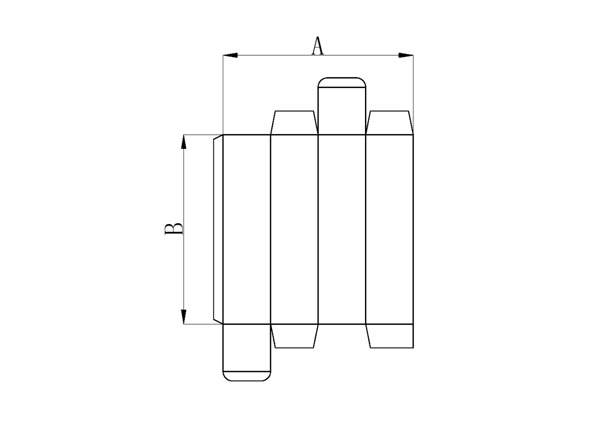

Size of two-sides glue box and folded box:

|

Item/model |

780Type |

980 Type |

1050 Type |

1450 Type |

|

|

A |

MAX |

650 |

850 |

900 |

1200 |

|

MIN |

150 |

150 |

200 |

200 |

|

|

B |

MAX |

700 |

800 |

1000 |

1000 |

|

MIN |

80 |

100 |

100 |

100 |

|

|

H |

MAX |

50 |

50 |

50 |

50 |

|

MIN |

10 |

10 |

10 |

10 |

|

|

Main Tech Data/Model |

GK-780SLJ |

GK-980SLJ |

GK-1050SLJ |

GK-1450SLJ |

|

Paper Material |

Cardboaed250-700g |

|||

|

Max. Liner speed |

220m/min |

|||

|

Feeding way |

Automatically and continuously feeding |

|||

|

Way of folding in reverse |

Fold 1 and fold 3 are 180° |

|||

|

Glue |

Water-base cold glue |

|||

|

Power Supply |

3P380V50HZ |

|||

|

Main motor power |

7.5kw |

7.5KW |

11KW |

11KW |

|

Total power |

9.7kw |

9.7kw |

13.2kw |

15kw |

|

Weight |

7T |

8T |

10T |

12T |

|

Overall dimension |

13×1.6×1.4 |

13×1.8×1.4 |

13×2.1×1.4 |

16X2.3X1.4 |

Brief introduction:

Feeding section:

a.auto feed correctly and continuously, internal of feeding is adjusted by continuously variable speeder;

b. independent high-speed feeding bell can be easily adjusted;

c. independent vibrating motor can improve feeding greatly;

d. feeding blade and baffle on the left and right can be adjusted upper and down to shorten adjusting and carton changing time.

Folding:

a. long-distant folding ensure the first line

180°, the third 135° to easily open the cartons fully filled;

b. all parts can be easily replaced, which is convenient to install other components for other kinds of cartons.

Bottom folding:

a. The entire bottom-lock part is installed in a reversible bracket, substantially reduce the swap adjustment time of bottom-fold box and the other types of box.

b.Bottom-folding speed is 50-400 pcs per min, stable and reliable.

gluingbucket

a.upper gluing bucket can adjusted separately up and down,right and left,to ensure the gluing quality

b.bottom gluing bucket can be adjusted right and left,set gluing amount,east to assemble,disassemble and clean

Folding:

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection.

Full pressing

a. Pressure can be adjusted conveniently, reliable, ensure good quality of gluing

b. With counting device to count the finished boxes to match with boxes regulating, easy to count and pack

Transmission

Structure is specially designed, pressure adjustment is easy and reliable to ensure the quality of gluing;

Collecting:

Press is equipped with independent speeding device, the operator can set the paper collecting speed according to the packing speed.

Spraying System

Equipped with three guns, convenient in the production of 4/6 corner box and various special-shaped box, gluing quickly and accurately sizing.

Servo motor

The servo control system, assistant with PLC and signal collection operation system, to fold each product (4, 6 corners box) correctly, ensure perfect quality.