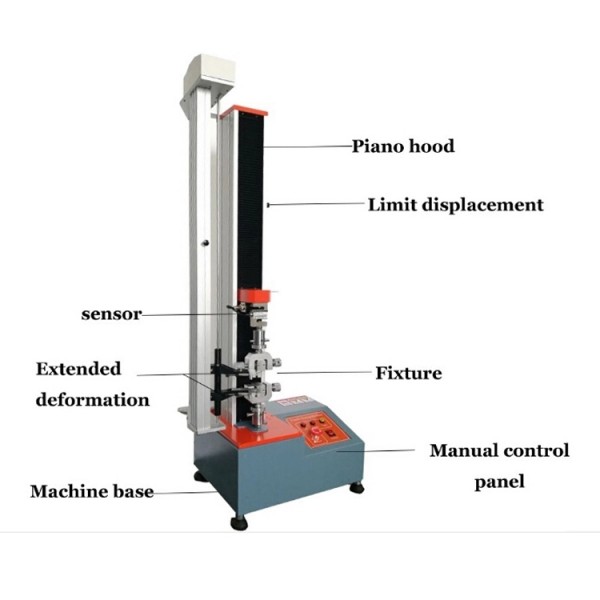

universal tensile machine,compression testing machine

Plastic, Polymers Materials Tensile Testing Machine

Summary:

Plastics, polymers and composites can be tensile tested to measure product quality. Tensile tests measure the load required to break a plastic test sample and specimen stretch or elongation to that breaking load. The resulting test data helps specify materials, design parts to withstand forces, and key quality control checks for materials. Plastic composite tensile test equipment, testers and electromechanical universal test machines feature constant rate of crosshead extension or CRE because plastics tensile test behavior is time rate test speed dependent. Plastic tensile coupons (dogbone-shaped specimens with defined width and load stress psi) are made to ASTM, EN, DIN and ISO tensile test sample dimensions. Plastics composite tensile tester machine speed should always rely on standard specifications. Plastic tensile test standards ASTM D638 and ISO 527 both require axial extensometers to measure strain below 20 percent extension values. High travel or strain can be measured by the machine crosshead or digital encoder. Thin film sheet samples should follow ASTM D882.

Applicable Testing Standards

- ISO 527 - Tensile Test of Plastics Composites

- ASTM D638 Tension Testing for Plastics

- ASTM D882 Tensile Testing for Thin Plastic Sheeting

- ASTM D3039 Tensile Testing for Advanced Composite Materials

ASTM D638 Tension Testing for Plastics

ASTM D638 is one of the most common plastic strength specifications and covers the tensile properties of unreinforced and reinforced plastics. This test method uses standard “dumbell” or “dogbone” shaped specimens under 14mm of thickness. A universal testing machine (tensile testing machine) is needed to perform this test.

Test Procedure:

- Cut or injection mold your material into one of the five “dumbbell” shapes. The exact shape you use is dependent upon your material’s rigidity and thickness.

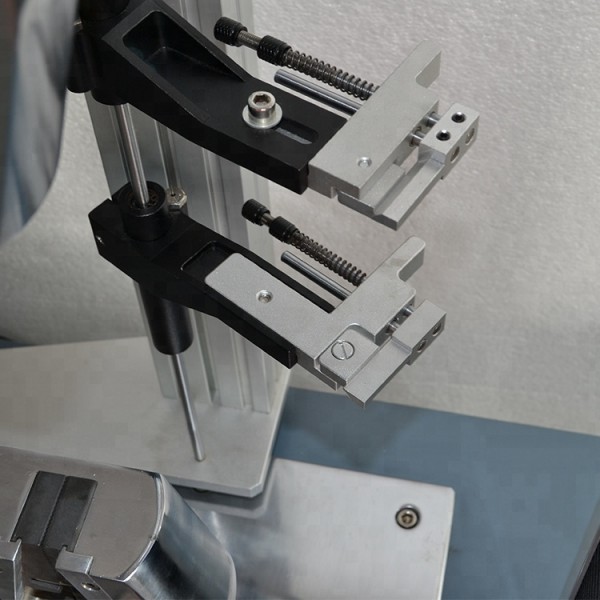

- Load the specimen into tensile grips.

- Attach the extensometer to the sample

- Begin the test by separating the tensile grips at a constant rate of speed. Speed depends on specimen shape and can range from 0.05 – 20 inches per minute. The target time from start of test to break should be from 30 seconds to 5 minutes.

- End the test after sample break (rupture)

Specifications:

|

Items |

Plastic, Polymers Materials Tensile Testing Machine |

|

Capacity |

2, 5, 10, 20, 50, 100, 200Kg |

|

Unit |

G, KG, N, LB can be exchanged |

|

Accurate Grade |

0.5grade |

|

Display Device |

PC |

|

Resolution |

1/250,000 |

|

Effective Accuracy |

±0.2%(0.5grade) |

|

Max.Stroke |

600mm |

|

Speed Range |

0.01-500mm/min (adjustable ) |

|

Motor |

Servo Motor + High Precise Ball Screw |

|

Elongation Accuracy |

0.001mm |

|

Power |

AC220V, 50/60HZ(custom-made) |

|

Standard Accessories |

Tensile clamp, Tool kit, Computer system, English software CD, User manual |

Recommended Plastic, Polymers Materials Tensile Testing Machine

Our Model DZ-106, Servo Universal Tensile Tester with Extensometer

Common Tensile Grips

factory Research and Development Prodessional Extensometer

Professional designed software. PC to view test results, analysis of data and graph

Our Services

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-con.

Pre-sales service

24-hour Online contact

Choose the right model of the equipment

according to customer's request

Middle service

Give the best offer

Support customization

Do customer's request

Choose payment term you convenient.

Promptly production and delivery inform you in time.

Can provide invoice value as you like to decrease your tax

After sale service

1 year warranty service and all life maintenance

Provide Free information (1. Product Instruction 2. Product

operation instruction/video 3. Experiment Test)

Remote control technical consult

Free installation DVD

Maintenance plan